Updating the fish hatchery’s infrastructure allows the historic facility to replenish smallmouth bass in local river systems.

By Molly Kirk/DWR

Photos by Meghan Marchetti/DWR

A leftover pipe from the 1930s reminds the staff of how far they’re come with the new Front Royal Fish Cultural Station renovations.

There’s a section of old pipe tucked into the corner of the original fish hatchery building at the Front Royal Fish Cultural Station in Front Royal. A relic from the 1930s when the fish hatchery was built, its tongue-and-groove wood planks are bound together by steel bands, and it used to connect the waters of Passage Creek with the ponds of the hatchery. It’s a vivid reminder of the past as the hatchery moves forward into the future.

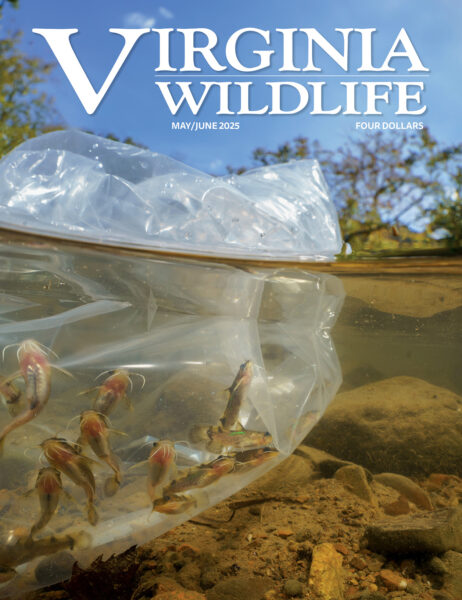

Constructed by Civilian Conservation Corps workers starting in 1931, the Front Royal fish hatchery completed its first fish stocking of smallmouth bass and sunfish in 1933. Now, 90 years later, the hatchery is ushering in a new era after an extensive renovation. With the renovations, the Virginia Department of Wildlife Resources (DWR) is aiming to raise smallmouth bass at Front Royal in addition to musky and walleye, allowing the agency to not only enhance smallmouth populations in the South and Shenandoah rivers, but also to better understand them.

“Front Royal serves as a model for what we’d like to bring to the other facilities,” said DWR Hatchery Superintendent Brendan Delbos. DWR currently operates nine fish hatcheries— five cold-water and four warm-water. “It’s hopefully the start of good things to come for the hatchery system. On a regional level, it’s my prediction is that it’s going to have a great impact if things go as planned. We’re certainly taking good steps toward being able to rebuild the smallmouth bass population in that area.”

The smallmouth raised at Front Royal and stocked into the South and Shenandoah river watersheds will also provide DWR with some important data. “The aquatic biologists in Region 4, Steve Reeser and Jason Hallacher, have come up with a clever study that will allow us to see how these fish disperse after stocking,” said Delbos. “They’re going to be looking at any limitations that there might be in those systems that are preventing the smallmouth bass from really repopulating and taking off like we saw historically. We’re quite excited that fish raised at Front Royal will be used for scientific purposes in addition to providing recreational opportunities for anglers.”

Smallmouth bass stocked from the Front Royal fish hatchery will help inform biologists about the species in the South and Shenandoah rivers.

Into the 21st Century

Until 2020, the Front Royal hatchery produced primarily musky and walleye, and smallmouth in small numbers. The facility was also used to hold trout and catfish trucked in from other locations until their stockings into Northern Virginia waters.

In 2020, Front Royal ceased operation to begin renovations, which are in part made possible through the largest natural resources settlement in Virginia. A lawsuit brought by the Virginia Secretary of Natural Resources against a local chemical company resulted in a 2017 settlement that awarded funds earmarked for natural resources projects after the company was found to have been releasing mercury into the South River for many years. The mercury discharge impacted the river’s fish populations, especially the smallmouth. Part of the consent decree funded renovations to the Front Royal hatchery as a way to compensate Virginians for lost recreational fishing opportunities.

“Historically speaking, partially as a result of some of those releases, smallmouth bass populations in particular have nosedived over the years,” said Delbos. “As usual with fisheries issues, there are other confounding factors—loss of habitat, increase in water temperature—but certainly the chemical is something we can point to and say, ‘this was not a good thing for the population.”

Three years later, Front Royal has a new hatchery building with modern technology, a sophisticated filtration system for the water it pulls from nearby Passage Creek, and four ponds lined with rubber instead of an earthen bottom. Those facilities will enhance DWR’s capabilities to raise smallmouth bass, walleye, and muskellunge.

A aerial view reveals the Front Royal hatchery’s newly lined rearing ponds and new buildings for concrete raceways and hatchery.

“It certainly helps to bring the hatchery into the 21st century,” Delbos said. He characterized the filtration system installed at the dam on Passage Creek at the west end of the property, two state-of-the-art drum filters, as “a huge game-changer for the facility.” At capacity, the system can provide the hatchery with 2,000 gallons per minute of water free of other aquatic species, leaves, debris, and fish eggs.

The new drum filters remove other fish, debris, and contaminants from the water from Passage Creek before it flows to the hatchery.

That water flows into the new hatchery building, where modern equipment complete with digital readouts controls all aspects of the fish hatching and raising. “In a controlled setting in the hatchery, smallmouth bass are a very difficult species to work with,” said Delbos. “We now have state-of-the-art equipment, so we have the potential to dial in the water chemistry to meet the unique, specific requirements of smallmouth or whatever species we’re working with.”

That water from Passage Creek is of such a quality that even though Front Royal is designated a warm water hatchery, with the new hatchery equipment it also has the potential to raise or hold trout in the winter months. “That really adds to the flexibility and usefulness of the facility,” said Delbos.

A newly installed water intake system removes debris from Passage Creek’s water before it flows into the filtration drums.

Another new building houses high-tech cement raceways for spawning fish, juvenile fish, and fish the facility will hold for stocking. From those raceways, young smallmouth will be transferred to the newly lined ponds to continue to grow until they’re collected and stocked into the South and Shenandoah rivers.

The lined ponds, complete with aerators to provide oxygen, will enable hatchery staff to conserve water, reduce maintenance, and capture the fish more safely for stocking. “Considering all the time, money, effort that we put into raising these fish, we want to do everything we can to make sure that we’re maximizing survival,” said Delbos. “The pond modifications, including the liners, are going to help us do that.”

Institutional Knowledge, Cutting-Edge Technology

Front Royal hatchery manager Wayne Pence was excited to open the valves on the hatchery after the celebratory ribbon-cutting ceremony in May. Pence started working at Front Royal in 1983 and has spent more than 35 years raising fish in the squat stone building built in 1931, using much of the same equipment and techniques of those early days. “It wouldn’t have looked much different back then,” he said as he gazed at the large, open space, metal tanks, and aging nets hanging on the walls.

The Front Royal hatchery operated in its original 1930s building for almost 90 years.

Pence noted that the main challenge in raising fish in the old hatchery building was maintaining the consistency of temperature and water quality that fry and juvenile fish need to survive. Water was piped into the hatchery directly from Passage Creek and could carry in bacteria or other fish species and eggs.

“The new system has not only the filtration drums at the dam in the creek, but also a UV filter at the hatchery building. We have oxygen in the tanks, and we can control the water temperature,” Pence said. “All that will help us increase our hatching rates and decrease our mortality rates. When you have a consistent temperature and filtered water, it keeps the fish healthier.”

Pence laughed when asked if there’s an instruction book for all the valves and digital screens of the new hatchery system. He pointed to a thumb drive hanging from a valve.

“There it is. I’m learning a lot!” he said.

Pence learned the ins and outs of growing fish at Front Royal from former hatchery manager Ken Mitchell and former hatchery foreman Earl Wakeman. Wakeman’s father had helped build the facility in the ’30s. The hatchery is actually built on former Wakeman family land. The institutional knowledge here runs deep, and combined with the new technology, will serve DWR well.

“Hats off to Wayne. He was our point person during construction, and we couldn’t have done it without him,” said Delbos, who also credited DWR’s former Region 4 Fisheries Manager Paul Bugas for leading the project’s start. “Now that we’ll be raising fish out there, Wayne’s knowledge of the area, knowledge of the fish, and knowledge of the facility will be valuable. I’m very excited to have Wayne get his hands wet again. Front Royal is one of DWR’s most historic hatcheries, and now it’s also one of its most advanced in technology.”

Left to right: DWR Hatchery Manager Wayne Pence, DWR Hatchery Superintendent Brendan Delbos, DWR Chief of Fisheries Dr. Michael Bednarski, and DWR Executive Director Ryan Brown cut the ribbon for the May opening of the updated Front Royal Fish Cultural Station.

This article originally appeared in Virginia Wildlife Magazine.

For more information-packed articles and award-winning images, subscribe today!

Learn More & Subscribe